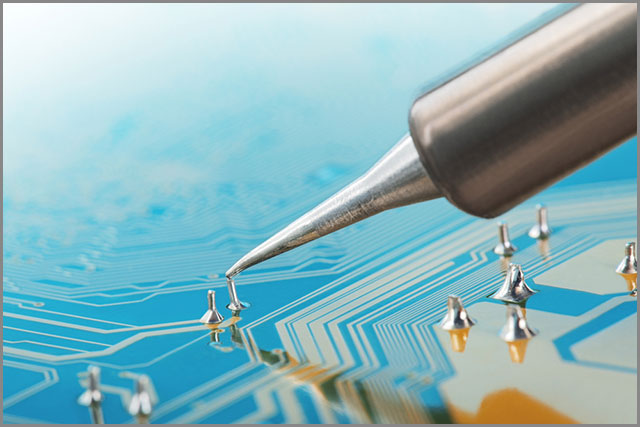

Using molten solder, two metals may be joined together. Its purpose is to provide a stable connection between any two electrical parts. Solder is an alloy that may be utilised with many different metals. And it’s made by pouring molten iron and tin-lead into a mould. Things like circuit boards and copper joints may be permanently connected by soldering.

Soldering uses lead-based solders. Therefore, brass, copper, and tin are the metals of choice. Soldering is required to make a connection that will enable electricity to flow.

Table of Contents

Soldering Varieties

Soft soldering is a common technique in the plumbing and electronics industries. It links electronic components on circuit boards and establishes an electrical connection. All solder joint methods employ the one with the lowest metal melting point.

When soldering is done with a lot of pressure

Compared with soft soldering, the connection formed by hard soldering is far more robust. Metallic silver or brass is often used for this purpose. A blowtorch to raise the temperature and melt the base metal needed to form a strong joint is essential for reinforcing the connection. The place where it is heated forms a strong bond as it cools. Joining copper or brass components requires the use of silver solder.

High-temperature brazing

In contrast to hard and soft solder, this kind has a greater melting point. You won’t obtain the greatest results until you heat the material to the right temperature.

Smelting Solder Flux

The flux core, often known as a coil or wire, is a reducing agent employed at the site. During the soldering process of solder joint, flux is released. It creates an unambiguous electrical connection by reversing the oxidation of metals at the point of contact.

Applications of Soldering

Soldering may be used in a wide variety of contexts. The use determines the kind of solder used. Tin, for instance, is a material used in electronic solder, roofing, and sheet metal.

The many applications of soldering are as follows

Metal Gutters Need to Be Soldered

Installing a gutter system is a smart investment for any house. If your property has a metal gutter, its pieces were likely soldered together. The solder connection between the two pieces is durable and watertight.

Electricians’ Soldering Guide

As was noted before, the soldiers also generate an electrical current. Soldering is a reliable way to join wires in commercial or home wiring, ensuring uninterrupted power delivery. As a bonus, it may be used to join wires to terminals on the back of a control panel or the inside of any other electrical equipment.

Put some solder on it: auto maintenance

Solder joint may be made more secure and flaws eliminated thanks to solder. Due to its strength, it cannot fix engines, but it is useful in other ways.

Supplies for soldering at home

Home chores like joining circuit boards or repairs that need a great deal of heat and control might benefit significantly from soldering equipment. You can solder in the comfort of your home with a soldering pencil, gun, or iron.

Plumbers can’t do their jobs without soldiers. When joining copper pipes, lead-free solder is the preferred method. When the temperature in the joint region has to be raised quickly, equipment like a soldering gun or a roofer’s soldering iron may help.